Best quality Choke Manifold Parts - Manifolds – CEPAI

Best quality Choke Manifold Parts - Manifolds – CEPAI Detail:

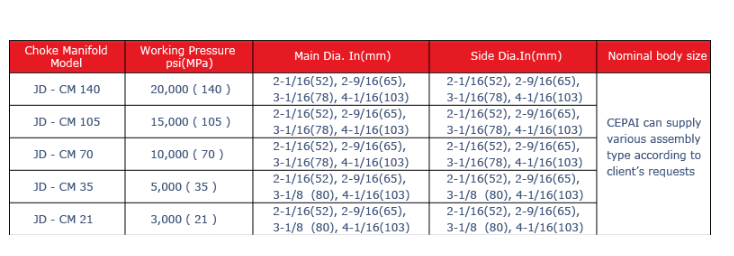

Choke Manifold is adopted to execute new drilling-well’s technique of balance pressure. Choke Manifold can avoid pollution of oil-layer and improve the speed of drilling and control blowout effectively. The choke manifold consists of choke valves, gate valves, line pipes, fittings, pressure gauges and other components. CEPAI Drilltech supplies various choke manifold from 2-1/16″~4-1/16″, with working pressure 2,000PSI~20,000PSI as per API SPEC 16C /6A.

Kill manifold is necessary equipment in well-control system to pump drilling fluid into well barrel or inject the water into wellhead. It consists of check valves, gate valves, pressure gauges and line pipes. CEPAI supplies various kill manifold from 2-1/16″~4-1/16″, with working pressure 2,000PSI~ 20,000PSI as per API SPEC 16C /6A.

Drilling Mud Manifolds

Drilling mud manifold consists of mud valve, high pressure spherical union, high pressure core union, tee, high pressure hose, elbow, pressure gauge, and pup joint etc. CEPAI Drilltech supplies various mud manifold from 2″~4″, with working pressure 2,000PSI~10,000PSI as per API SPEC 16C /6A

Standard configurations of surface test trees are available. These typically consist of swab, upper master, production, and kill line valves. Designs are also availablewith the lower master valve located beneath the swivel. Surface Test or Well Intervention Trees come in sizes from 3 1/16″ to 7 1/16″ and 5,000 psi through 15,000 psi (temperatures from –50°F to 350°F). Custom configurations are also available upon request.

High Pressure Choke & Kill Manifolds

By incorporating components such as Adjustable and Positive Chokes, Hydraulic Drilling Chokes, API Flanges, Hammer Lug Unions, API Studded Crosses and Tees, Adaptors, Spools, Blinds, Crossovers and Fittings, Choke Control Console, High Pressure Manifold Fittings, High Pressure Gate Valves (Manual and Hydraulic Gate Valves), High Pressure Plug Valves, Forged Crosses, Forged Tees, Forged Long Radius Elbows, Pressure Tested Assembly, Individually Pressure Tested Fittings and Gate Valves, Mud Vales, Drop Forged Manifold Fittings, Chokes, High Pressure Choke Valves, High Pressure Check Valves, Hammer Union Forged Tees and Elbows a depending on the application from our own stock availability, CEPAI can control the quality and programming of even very complex systems. CEPAI is keen to work with clients to provide the right solution for individual projects. Where applicable or to meet client requirements and are supplied fully certified by independent third party authorities.

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Best quality Choke Manifold Parts - Manifolds – CEPAI , The product will supply to all over the world, such as: Victoria, Thailand, Estonia, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.