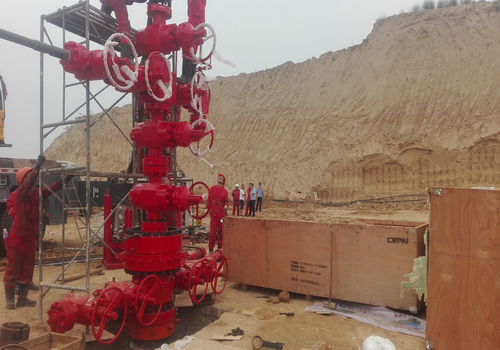

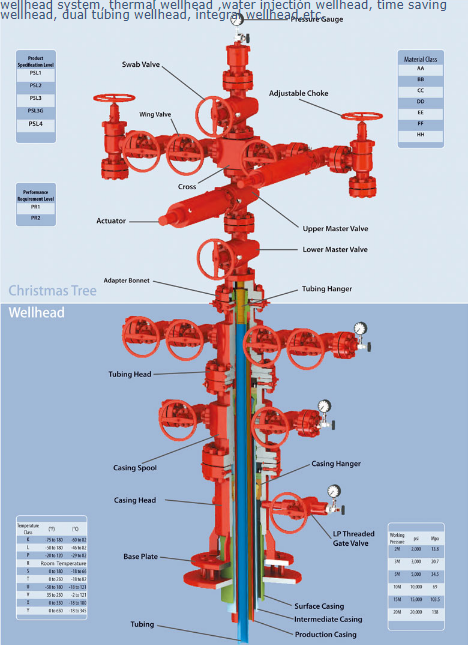

Christmas Tree and Wellheads

Wellhead and Christmas tree by CEPAI are used for well drilling and oil or gas production, water injection and downhole operation. wellhead and Christmas tree is installed on the top of a well to seal the annular space between casing and tubing, can control wellhead pressure and adjust well flow rate and transport oil from well to pipe line.

We manufacture the wellhead and Christmas tree in according with API 6A standards totally, also can be supplied to meet the complete material class, temperature range and PSL& PR level requirements. We have lots of type of wellheads for OEM choice, such as conventional spool wellhead, ESP wellhead system, thermal wellhead, water injection wellhead, time saving wellhead, dual tubing wellhead, integral wellhead.

Design Specification:

Standard Christmas Tree and Wellheads are in accordance with API 6A 21th latest Edition, and use the right materials for different operating condition according to NACE MR0175 standard.

Product Specification Level: PSL1 ~4 Material Class: AA~HH Performance Requirement: PR1-PR2 Temperature Class: LU

| Name | Christmas Tree & Wellheads |

| Model | Typical Christmas Tree/Geothermal Wellheads/Multiple Wellheads etc |

| Pressure | 2000PSI~20000PSI |

| Diameter | 1-13/16”~7-1/16” |

| Working Temperature | -46℃~121℃(LU Grade) |

| Material Level | AA、BB、CC、DD、EE、FF、HH |

| Specification Level | PSL1~4 |

| Performance Level | PR1~2 |

Product Features:

Design, manufacturing, testing and material are all followed by API 6A standard strictly

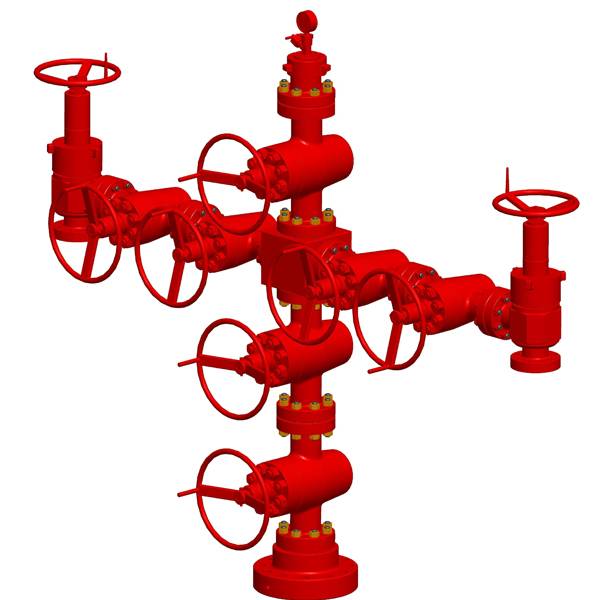

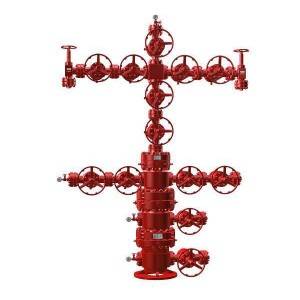

mainly included tubing head, gate valve, choke valve, top flange, cross and so on

Main Structure of split type, integrated type and double pipe type

Can be controlled remotely by a certain number of safety valves and control systems

Fire safe and explosion-proof function are available

Christmas trees are safe and reliable. Easy and convenient operation and maintenance

More Features:

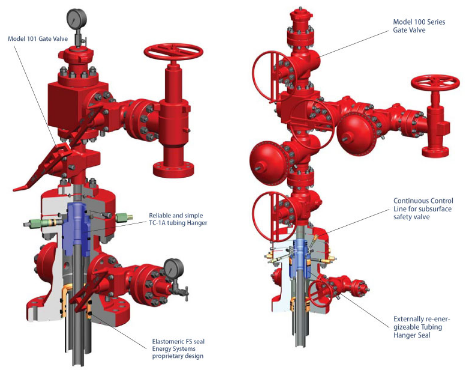

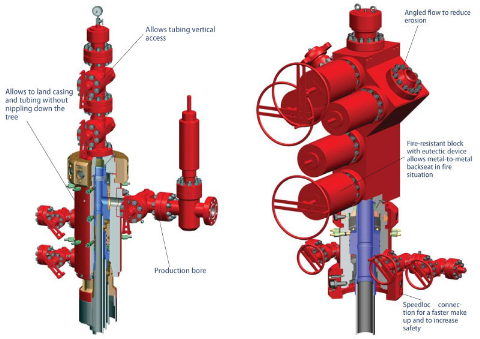

BASIC SINGLE COMPLETION

Developed for applications where economics are the major driver. This is achieved without compromising quality or safety.

Features and Benefits

◆ Available up to 5,000 psi wells and completion sizes up to and including 3 1/8".

◆ Suitable for slightly sour and corrosive environments.

◆ Utilizes Energy Systems' proprietary interference elastomer seals and elastomer seal compound.

ADVANCED SINGLE COMPLETION

Developed for applications where production conditions are known or predictable. This concept includes Energy Systems' proprietary elastomer seals designs and our "state of the art" Model 120/130 gate valves.

Features and Benefits

◆ Available up to 15,000 psi wells and completion sizes up to 4 1/16".

◆ Suitable for sour, corrosive environments and when producing in environmentally sensitive areas or in close proximity to the densely inhabited areas (AA to FF).

◆ Production environments include oil, gas, gas lift and all flooding and injection operations when corrosion may be an issue.

◆ Available with or without control-line porting. Multiple ports are available if required.

◆ Certified to API 6A, Appendix F, PR-2 plus additional cycle testing as required by CEPAI.

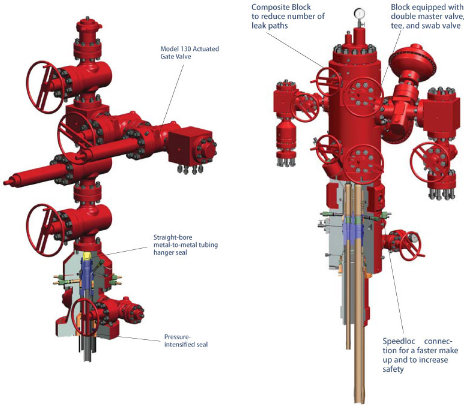

CRITICAL SERVICE SINGLE COMPLETION

Developed for the most severe production requirements. Includes Energy Systems' patented metal-to-metal seal technology and the totally non elastomeric Model 120/130 gate valve.

Features and Benefits

◆ Available up to 20,000 psi wells and completions sizes up to and including 7 1/16".

◆ Suitable for sour, corrosive environments and when producing in environmentally sensitive areas or in close proximity to the densely inhabited areas (AA to HH).

◆ Production environments include primarily high pressure and high-temperature gas production.

◆ Depending on the component, surface temperature rating can be as high as 450°F.

◆ Available with or without continuous control-line porting. Multiple ports are available if required.

◆ Utilizes Energy Systems' patented metal-to-metal sealing technology.

◆ Certified to API 6A, Appendix F, PR-2 plus additional 300 cycles as required by CEPAI.

DUAL COMPLETION

Developed for all multiple tubing string completions. The composite block can be configured where it is best suited for the Operator's well site. Valves can be all front facing or alternate where the long string faces one direction and the short string 180° offset.

Features and Benefits

◆ Available up to 10,000 psi wells and completions sizes up to and including 4 1/16".

◆ Suitable for sweet or sour, corrosive environments.

◆ Production environments include oil, gas, gas lift and all flooding and injection operations.

◆ Available with or without control-line porting. Multiple ports are available if required.

◆ Energy Systems designs for minimal overall height and maximum access. This translates into costs savings and safer operating conditions for the production operators.

◆ Utilizes Energy Systems' proprietary interference and elastomer seals and elastomer seal compound.Is available with metal-to-metal sealing if required.

◆ Certified to API 6A, Appendix F, PR-2 plus additional cycle testing as required by CEPAI.

ELECTRIC SUBMERSIBLE PUMP COMPLETIONS

Developed for ESP or ESPCP applications. Energy Systems has standardized on penetrator options to fulfill all the Operator's requirements without losing sight of the need to maintain a cost-effective system.

Features and Benefits

◆ Available up to 5,000 psi wells and completion sizes up to and including 4 1/16".

◆ Designed for Class 1 Division 1, non-Class 1 Division 1, or simple cable packoff penetrator options.

◆ Penetrator options have been rationalized to offer flexibility and ease of installation.

◆ Suitable for sweet or sour and corrosion environments.

◆ Production environments include oil and are compatible with injection operations when corrosion may be an issue.

◆ Available with or without control-line porting. Multiple ports are available if required.

◆ Utilizes Energy Systems' proprietary interference and elastomer seals and elastomer seal compound.

◆ Certified to API 6A, Appendix F, PR-2 plus additional cycle testing as required by CEPAI.

TUBING-LESS COMPLETION/FRAC FLOW SYSTEM

Developed for artificial lift applications for Rod Pumps and Progressing Cavity Pumps (PCP). To better serve the artificial-lift market, Energy Systems has added Integral Production BOPs (IPBOP) to our product portfolio. The IPBOP allows the Operator to safely re-enter the well bore by sealing off against the rods or, if the rods are parted, allows one to blind off the well bore.

Features and Benefits

◆ Available up to 2,000 psi wells and completion sizes up and including 4 1/16".

◆ Suitable for sour, corrosive environments and when producing in environmentally sensitive areas or in close proximity to the densely inhabited areas (AA to FF).

◆ Production environment is oil but can be adapted to be suitable if adjacent injection operations create a more corrosive environment.

◆ Although independent components can be provided, the Integral Production BOP (IPBOP) can integrate the tubing head bonnet, production BOP and flow tee, or any combinations of these, in one unit.

◆ The Integrated BOP offers cost savings when compared to purchasing the individual items. In addition, potential leak paths are greatly reduced, and the overall height, which can be 50% less, is safer for Production Operators.

◆ The BOP rams have the capability to seal off from 0 to 11/2" rods.

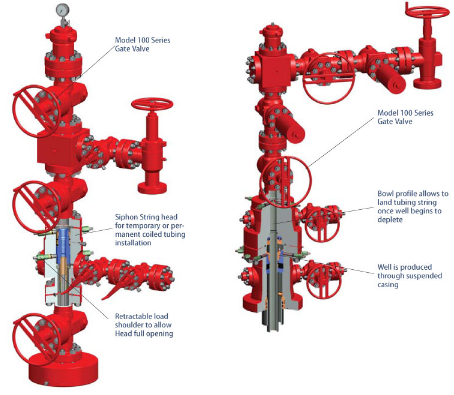

COILED TUBING COMPLETION

Developed to allow operators to continue production from natural-lift oil and gas wells without major workovers. Energy Systems has experienced various applications of coiled tubing, including uses as initial production tubing to replace the jointed pipe, and use as a velocity string in existing completions, being snubbed into an existing well, artificial lift, gas lift, ESP completions and dual concentric strings.

Features and Benefits

◆ Increases savings by reducing the time the drilling rig stays on location.

◆ Minimizes the tubular cost by reducing the hole and casing sizes.

◆ Faster completion than conventional rig and jointed tubing.

◆ Prevent formation damage associated with kill fluids.

◆ Available in all popular API thread and flange connections or combinations of both.

◆ Pressure ratings are comparable to rated pressure of coiled tubing.

INTEGRAL PRODUCTION BOP FOR ROD & PROGRESSING CAVITY PUMPS

Developed to support well fracturing operations in today's natural gas completion processes. In addition, the system works well for applications where high production rates deplete rapidly and a siphon string is to be added at a later date to further enhance production. The smaller tubing head flange allows for economical temporary tubingless completions and for traditional tubing completions. This type of completion eliminates the need for wellhead isolation tools and tree savers during the well fracturing job, saving time and money. The system supports standard jointed tubing or coiled tubing completions.

Features and Benefits

◆ Available up to 15,000 psi wells.

◆ Suitable for sour, corrosive environments and when producing in environmentally sensitive areas or in close proximity to the populous (AA to HH).

◆ Eliminates the need for Wellhead Isolation tools and Tree Savers reducing rental tool cost.

◆ Reduces fracturing stack rental costs because of the smaller size.

◆ Allows a siphon string to be run through the XT, landed, and packed off. The bigger-bore XT can then be removed and replaced with a more economical tree compatible with tubing size and production pressures of the flowing well.

◆ Also available for use with the DTO Wellhead System providing additional drilling time and completion savings.

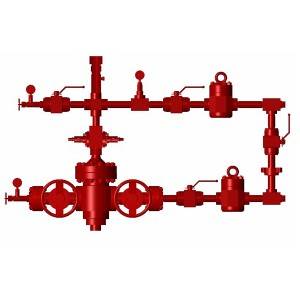

HORIZONTAL COMPLETION

Developed to allow well intervention to occur without removing the XT and flowline. This allows the Operator to maintain flowline connections, thus, reducing cost associated with reconnecting the well and enabling the well to be brought back onstream quicker.

Features and Benefits

◆ Available up to 10,000 psi wells and completion sizes up to and including 9".

◆ Suitable for sour, corrosive environments and when producing in environmentally sensitive areas or in close proximity to the densely inhabited areas (AA to HH).

◆ Production environments include oil, gas and gas lift.

◆ Greatly simplifies access to the tubing string for workovers.

◆ Provides easier access for the Production Operator to the gate valves.

◆ On bigger-bore completions, can greatly reduce height required for the wellhead deck.

◆ Available with or without control-line porting. Multiple ports are available if required.

◆ Utilizes Energy systems' proprietary interference elastomer seals and elastomer seal compound and our patented metal-to-metal seal technology.

◆ Certified to API 6A, Appendix F, PR-2 plus additional cycle testing as required by CEPAI.

LARGE - BORE COMPLETION

Developed for higher-volume flow rates and applications where erosion due to those flow rates might be an issue. This concept employs Energy Systems' latest technology in metal and elastomer seals and the Model 120/130 gate valve.

Features and Benefits

◆ Available up to 15,000 psi wells and completions sizes up to and including 7 1/16".

◆ Suitable for sour, corrosive environments and when producing in environmentally sensitive areas or in close proximity to the densely inhabited areas (AA to HH).

◆ Production environments include primarily high pressure and high-temperature gas production.

◆ Depending on the component, surface temperature rating can be as high as 450oF.

◆ Available with or without continuous control-line porting. Multiple ports are available if required.

◆ Utilizes Energy Systems' patented metal-to metal sealing technology.

◆ Certified to API 6A, Appendix F, PR-2 plus additional 300 cycles as required by CEPAI

TUBING CONVEYED ESP

Developed to allow the submersible pump to be retrieved with minimal well intervention and with a coiled tubing unit. The well is produced out of the annulus; thus, the flowline stays intact during any well intervention. A recognized disadvantage of ESPs is inherent maintenance that is required on any downhole pump. This design concept allows the maintenance to occur in a fraction of the time with conventional ESP completion methods.

Features and Benefits

◆ Ability to retrofit existing wells and new well drills.

◆ Continuous flowline connection with BOP intervention.

◆ Complete well serviceability under "live well" conditions.

◆ Isolation of electrical cable and cable splice.

◆ Quick workover and recompletion connections.

TLP / SPAR COMPLETION

Developed to provide a dry tree access to a subsea wellbore from a tension leg platform (TLP) and SPAR.

Features and Benefits

◆ Single and dual casing riser design standards for all top tension riser applications.

◆ Available up to 15,000 psi wellhead and completion sizes up to 7 1/16".

◆ Fatigue-resistant length adjustment hangers and riser joints for accurate and fast riser hang off.

◆ Riser load measurement capability that allows simple installation and maintenance.

◆ Compact designs that minimize weight and height for the tight well spacing and riser weight restrictions of deepwater dry completion units.

◆ Use of intermediate pressure rated valves (6,650 psi) for weight savings.

◆ Multiple ports and continuous control lines.

◆ Utilizes Energy Systems' patented metal-to metal seal technology.

◆ Integral design of access platforms allow for safe personnel access in tight space conditions.

Production Photos