Professional Design Cryogenic Gate Valve - Manual Gate Valve for API6A Standard – CEPAI

Professional Design Cryogenic Gate Valve - Manual Gate Valve for API6A Standard – CEPAI Detail:

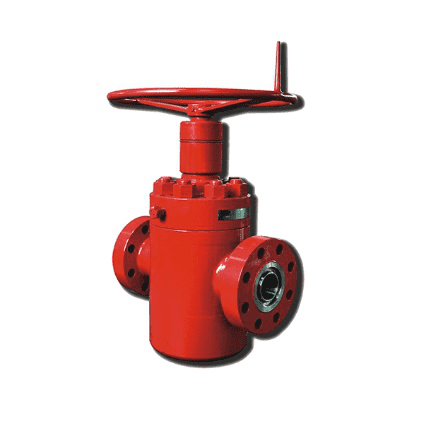

CEPAI’s FC gate valve, featured by high performance and bi-directional sealing, is designed and manufactured according to world’s most advanced technology. It is a counterpart of FC gate valves that gives fairly good performance under high pressure service. It is applicable for oil and gas wellhead, Christmas tree and choke and kill manifold rated 5,000Psi to 20,000Psi. No special tools are required when it comes to replace valve gate and seat.

Design Specification:

Standard FC gate valves are in accordance with API 6A 21th latest Edition, and use the right materials for H2S service according to NACE MR0175 standard.

| Product Specification Level | PSL1 ~4 |

| Material Class | AA~FF |

| Performance Requirement | PR1-PR2 |

| Temperature Class | PU |

Parameter

| Name | Slab gate valve |

| Model | FC Slab gate valve |

| Pressure | 2000PSI~20000PSI |

| Diameter | 1-13/16”~9”(46mm~230mm) |

| Working Temperature | -60℃~121℃(KU Grade) |

| Material Level | AA、BB、CC、DD、EE、FF、HH |

| Specification Level | PSL1~4 |

| Performance Level | PR1~2 |

Product Features:

Technical Data of FC Manual Gate Valve.

|

Size |

5,000 psi |

10,000 psi |

15,000 psi |

|

2 1/16″ |

√ |

√ |

√ |

|

2 9/16″ |

√ |

√ |

√ |

|

3 1/16″ |

√ |

√ |

|

|

3 1/8″ |

√ |

||

|

4 1/16″ |

√ |

√ |

√ |

|

5 1/8″ |

√ |

√ |

√ |

|

7 1/16″ |

√ |

√ |

Technical Data of FC Hydraulic Gate Valve

|

Size |

5,000 psi |

10,000 psi |

15,000 psi |

20,000 psi |

|

2 1/16″ |

√ |

√ |

√(with lever) |

√(with lever) |

|

2 9/16″ |

√ |

√ |

√(with lever) |

√(with lever) |

|

3 1/16″ |

√ |

√(with lever) |

√(with lever) |

|

|

3 1/8″ |

√ |

|||

|

4 1/16″ |

√ |

√(with lever) |

√(with lever) |

√(with lever) |

|

5 1/8″ |

√(with lever) |

√(with lever) |

√(with lever) |

|

|

7 1/16″ |

√(with lever) |

√(with lever) |

√(with lever) |

√(with lever)

|

More Features:

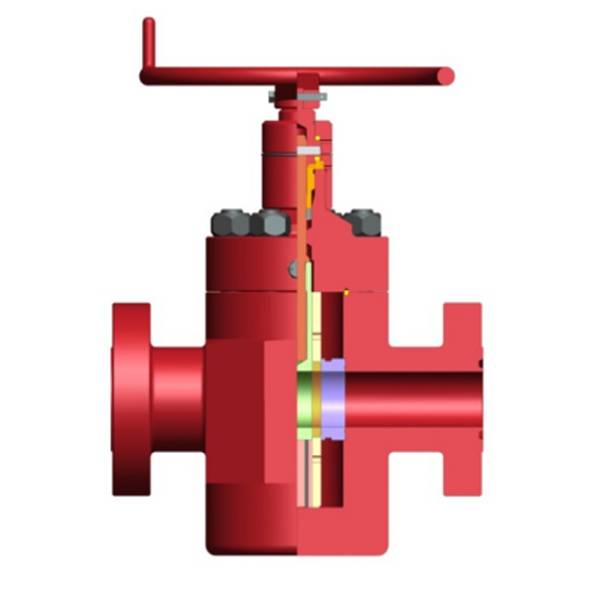

CEPAI’s FC and FLS gate valves are full bore design, effectively eliminate the pressure drop and Vortex, slowing down flushing by solid particles in the fluid, special seal type, and obviously reduce the torque of switching, metal to metal seal between the valve body and bonnet, gate and seat, the surface of gate overlay hard alloy by supersonic spray coating process and the seat ring with hard alloy coating, which have the feature of high anti-corrosive performance and good wear resistance, seat ring is fixed by fixed plate, which has good performance of stability, back seal design for the stem which can be easy for replacing packing under pressure, one side of bonnet is equipped with sealing grease injection valve, in order to supplement the sealing grease, which can improve the sealing and lubricating performance, and pneumatic (hydraulic) actuator can be equipped according to requirement of customer.

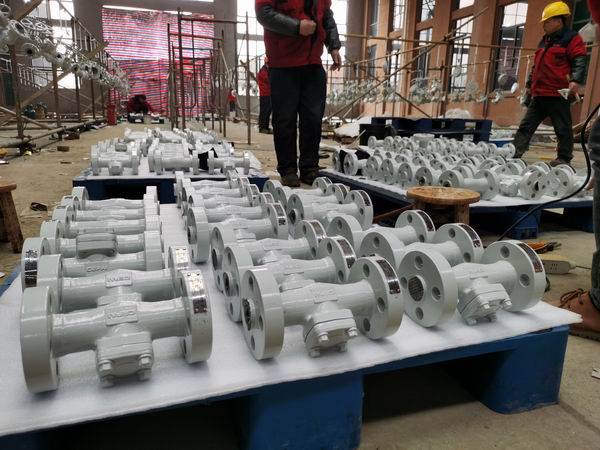

Production Photos

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Professional Design Cryogenic Gate Valve - Manual Gate Valve for API6A Standard – CEPAI , The product will supply to all over the world, such as: moldova, France, Victoria, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.