Rapid Delivery for Three Piece Ball Valve - External Sleeve Cage Chock Valve – CEPAI

Rapid Delivery for Three Piece Ball Valve - External Sleeve Cage Chock Valve – CEPAI Detail:

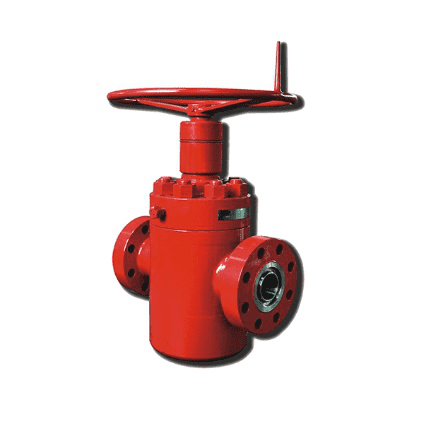

CEPAI’s Chock valves include Positive Chock Valve, Adjustable Chock Valve, Needle Chock Valve, External Sleeve Cage Chock Valve, these valves are offered by CEPAI to different countries, and all designs as per API6A Spec strictly, moreover, we can design and make the special chock valves based on different requirements. Their seats and valve needle made by hard alloy, which improves the corrosion resistance, flushing resistance performance, and material of throttle nozzle made of ceramics or hard alloy, the torque of Cage type choke valve is small torque, it can both adjust and cut off the fluid etc, controlling the flow rate by replacing the throttle nozzle of different sizes.

Design Specification:

Standard Chock valves are in accordance with API 6A 21th latest Edition, and use the right materials for H2S service according to NACE MR0175 standard.

Product Specification Level: PSL1 ~4 Material Class: AA~FF Performance Requirement: PR1-PR2 Temperature Class: LU

Product Features:

◆ Small impaction and noise of fluid

◆ Body/bonnet materials include carbon steel, alloy steel, stainless steel and duplex stainless steel

◆ In-line or angle body options

◆ Valves can be automated with electric or pneumatic actuators

◆ Metal to metal shut off in accordance with ANSI class VI & V

| Name | Chock Valve |

| Model | Positive Chock Valve/Adjustable Chock Valve/Needle Chock Valve/External Sleeve Cage Chock Valve |

| Pressure | 2000PSI~15000PSI |

| Diameter | 2-1/16”~7-1/16”(46mm~230mm) |

| Working Temperature | -46℃~121℃(LU Grade) |

| Material Level | AA、BB、CC、DD、EE、FF、HH |

| Specification Level | PSL1~4 |

| Performance Level | PR1~2 |

Positive Chock

Production Photos

Product detail pictures:

Related Product Guide:

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Rapid Delivery for Three Piece Ball Valve - External Sleeve Cage Chock Valve – CEPAI , The product will supply to all over the world, such as: Houston, Liverpool, Irish, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!