Ball valve is a key component in any piping system, providing a simple and effective way to control the flow of liquids and gases. Among the different types of ball valves available, two-piece ball valves are a popular choice due to their versatility and reliability. In this article, we’ll explore the uses of ball valves, when to use a two-piece ball valve, and the benefits of choosing a high-quality option from a reputable ball valve supplier.

What is the purpose of ball valve?

The main purpose of ball valves is to regulate the flow of fluids in pipes. It consists of a spherical disk (or ball) with a hole in the center, which can be turned to allow or prevent the flow of media. When the ball valve is in the open position, the hole is aligned with the pipe, allowing the media to pass through. When it is in the closed position, the hole is perpendicular to the pipe, blocking flow.

Ball valves are commonly used in a variety of industries, including oil and gas, petrochemicals, water and wastewater treatment, power generation, and more. They are favored for their ability to close quickly and reliably, as well as their ability to withstand high pressures and temperatures.

When should I use a two-piece ball valve?

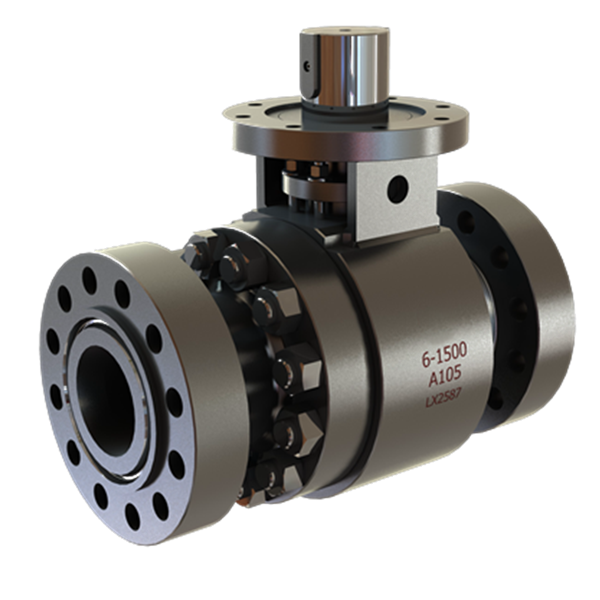

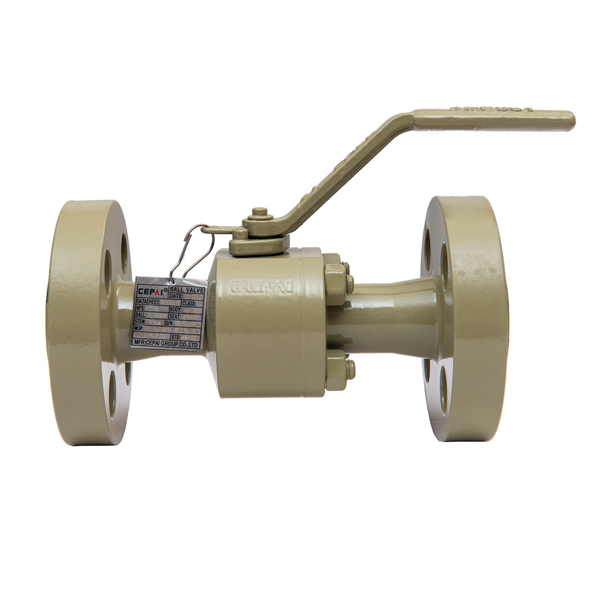

A two-piece ball valve is a special type of ball valve that consists of two separate parts, the body and the end cap. This design is easy to maintain and repair since the valve can be disassembled without removing it from the pipe. Ideal for applications that require regular maintenance or inspections, and systems that may need to be modified or upgraded in the future.

The two-piece cast fixed ball valve produced by CEPAI is mainly used to cut off or connect the medium in the pipeline. It can be used in water, steam, oil, liquefied gas, natural gas, coal gas, nitric acid, urea and other media. This makes it a versatile choice for a variety of industrial applications that may require control of different types of media. Additionally, the trunnion design ensures greater stability and support for the ball, allowing for higher pressures and larger sizes.

Choosing the right ball valve supplier is critical to ensuring valve quality and performance. Reputable suppliers like CEPAI offer a wide range of options to suit different requirements and their products are manufactured to international standards to ensure reliability and durability.

In conclusion, ball valves play a vital role in regulating the flow of fluids in pipes, and two-piece ball valves are a versatile and practical option for many applications. It is a popular choice across industries due to its ease of maintenance and repair and ability to handle a wide range of medium and high voltages. When selecting a two-piece ball valve, it is important to consider the specific requirements of the system and select a reliable supplier to ensure the quality and performance of the valve.

Post time: Jan-18-2024