Double Disc Check Valves: Introduction and Applications

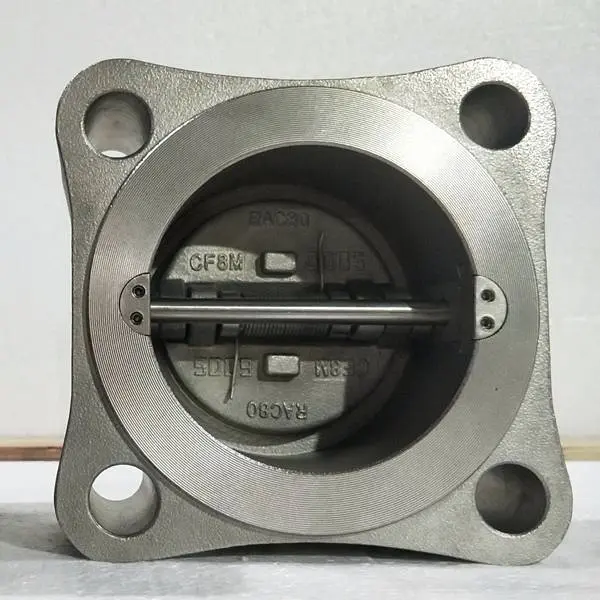

Double disc check valve is a commonly used fluid control device, usually used to prevent the backflow of fluid in the pipeline system. Its main structure includes valve body, valve disc, valve stem and valve seat. There are two valve discs inside the valve body, when the fluid passes, the valve disc moves outward with the flow of the fluid, when the fluid stops or reverses the flow, the valve disc returns inward to its original position with the action of the valve seat . The advantage of the double disc check valve is that it can prevent the reverse flow of the fluid and ensure the normal flow of the fluid in the pipeline system. It can also avoid fluctuations and oscillations to ensure the safe operation of the pipeline system. In addition, the double disc check valve also has the advantages of high efficiency, reliability, and simple maintenance.

Double disc check valves are widely used in chemical industry, petroleum, electric power, water treatment and other industries. In industrial production, it is often used to control the fluid flow in the pipeline system to ensure the safety, efficiency and stability of the production process. In addition, it can also be used to control the pressure of the pipeline system and prevent the leakage and damage of the pipeline system. In general, the double disc check valve is an efficient, practical and reliable fluid control device with wide application prospects. With the development of industry, the demand for double disc check valves is also increasing, so its production and sales prospects are very optimistic.

When choosing a double disc check valve, users need to consider many factors, such as pressure, temperature, material, etc. According to the different needs of the pipeline system, users can choose different types of double disc check valves to meet various industrial needs. Manufacturers of double disc check valves also need to pay attention to production quality to ensure product reliability and durability. At the same time, manufacturers also need to pay attention to the environmental protection of the production process to ensure that it meets environmental protection standards.

In addition, in order to ensure that the use of double disc check valves is more efficient and safe, users need to pay attention to the following points:

Installation position: The double disc check valve should be installed in the proper position of the pipeline system to ensure that it can effectively prevent the backflow of fluid.

Proper installation: The installation of the double disc check valve must be in accordance with the manufacturer's instructions to ensure that it can work properly.

Maintenance: The double disc check valve should be maintained and maintained regularly to ensure its normal operation.

Replace old parts: If any part of the double flap check valve is found to be faulty, it should be replaced in time to ensure its normal operation.

When using double disc check valves, you should also pay attention to comply with relevant national safety regulations to ensure the safety of users and the surrounding environment.

In general, the double disc check valve is a very effective fluid control device, which can effectively prevent the backflow of the fluid and ensure the normal operation of the fluid. In the pipeline system, the double disc check valve can prevent leakage, prevent turbidity, prevent blockage, and ensure the quality and safety of the fluid. If you need to use a double disc check valve, please be sure to choose a professional manufacturer and follow the manufacturer's instructions to ensure its correct use and long-term effective work.

When choosing a double disc check valve, you need to consider some factors, including material, size, flow rate, working pressure, operating environment, etc. You can choose the double disc check valve that suits you according to your needs. Double flap check valve also has many other excellent characteristics, for example, it has good corrosion resistance, high temperature resistance, impact resistance and so on. In the process of using the double disc check valve, you can use it for a long time without frequent maintenance and replacement. It has the advantages of simple structure, convenient use, simple installation and maintenance, and reliable operation.

To sum up, the double disc check valve is a very effective fluid control device, which has many excellent features and plays an important role in engineering. If you are looking for an efficient, practical, and reliable fluid control device, the double disc check valve is an excellent choice.

Post time: May-06-2023